Non-destructive testing (NDT) is an umbrella term for various techniques to evaluate the properties and conditions of materials and components without causing damage. NDT has long been used for quality control in manufacturing, maintenance inspections in industries like oil and gas, and detecting defects in the infrastructure sector.

However, recent years have witnessed a paradigm shift in the scope and significance of NDT testing worldwide. New technologies and materials have emerged on the horizon, calling for rigorous testing of their many complex components and processes for complete safety and reliability.

NDT emerges to the rescue, providing all the tools necessary to assess component integrity throughout the lifecycle. This article dives into the expanding role of NDT in lesser-explored, emerging sectors, and its role in ensuring safety, reliability, and sustainability.

Contents

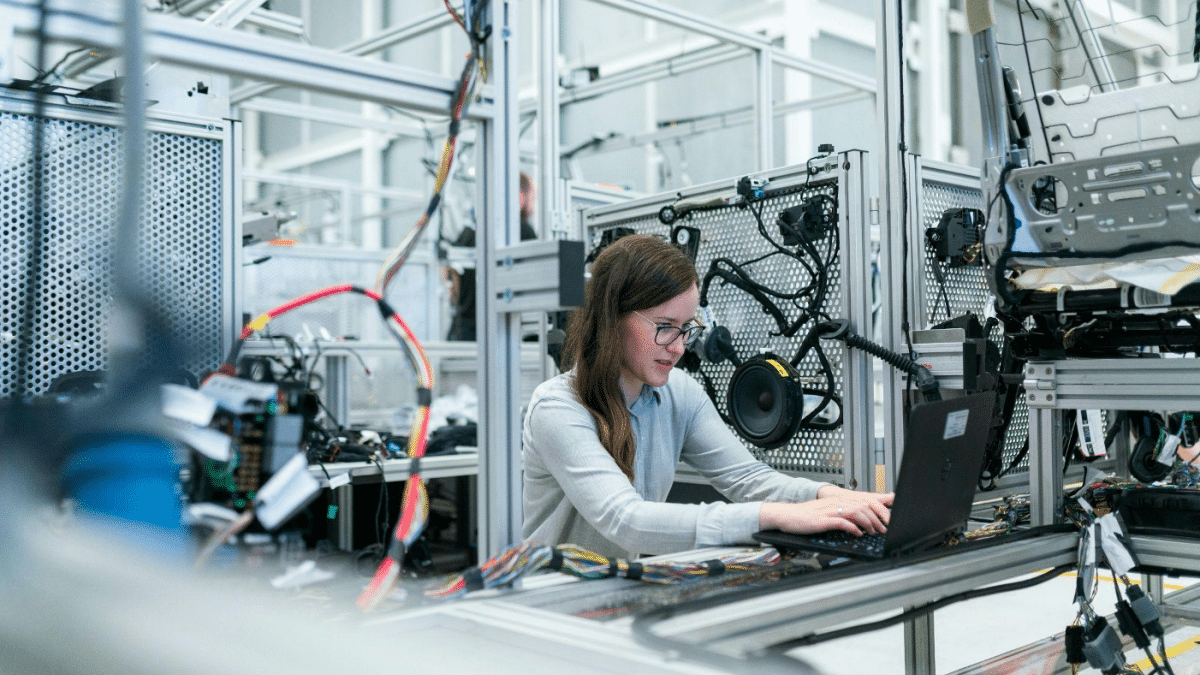

NDT in Advanced Manufacturing

One area where NDT is playing an increasingly crucial role is advanced manufacturing. Take for instance additive manufacturing, also known as 3D printing, which growing rapidly worldwide. NDT is leaving an indelible mark in the field with its advanced capabilities.

3D printing technology enables the production of complex components with intricate geometries. NDT helps inspect the 3D-printed parts for defects such as porosity, delamination, and cracks, thus ensuring thorough quality control.

Besides, NDT is also widely used in monitoring the quality of composite materials, increasingly used these days in aerospace, automotive, and construction industries. Composites are made from a combination of materials like fibers and resins, which translates to different properties depending on the manufacturing process. NDT helps ensure that these composite components comply with various strength, durability, and safety standards for holistic integrity.

Another example of NDT application in advanced manufacturing is in the inspection of nanomaterials. Given their unique properties and potential applications in various fields, nanomaterials call for careful inspection. NDT techniques can help characterize them and detect any defects at the nanoscale level. This ensures the safety and performance of nanomaterial-based products, paving the way for sustainable usage in the long term.

NDT for Sustainable Energy and Infrastructure

The energy sector, particularly renewable energy sources, relies heavily on the integrity of its infrastructure. Solar panels and wind turbines, for example, are consistently exposed to harsh environmental conditions that often lead to degradation and damage.

NDT techniques come in handy in such situations, helping inspect these components to identify potential defects such as cracks, corrosion, and delamination. Early detection means you can address these issues early on, thus ensuring the efficient and reliable operation of renewable energy systems.

NDT is also crucial to monitoring and maintenance of critical infrastructure like bridges, pipelines, and dams – all vital for the functioning of modern societies. Regular NDT inspections can help identify signs of fatigue, corrosion, and other defects, making sure they don’t compromise safety and performance. With this proactive approach to maintenance, operators can ensure the longevity and reliability of critical infrastructure.

NDT thus plays a crucial role not only in energy efficiency and sustainability but also in preventing failures and even catastrophic events. From preventing power outages and disruptions to essential services to helping avoid costly repairs to critical functions, NDT has become significant in protecting lives, property, and the environment.

Ensuring Safety and Reliability in Transportation with NDT

It goes without saying that the transportation and aerospace industries place a premium on safety and reliability. NDT techniques augment these goals by helping inspect aircraft components and structures for stringent airworthiness requirements.

NDT can help detect defects like cracks, corrosion, and fatigue, that can otherwise compromise the safety of aircraft. By identifying these flaws early on, NDT prevents failures and even catastrophic consequences.

In the railway industry, NDT can be used to monitor the condition of tracks, bridges, and other critical infrastructure. The technology helps detect defects like cracks, corrosion, and fatigue, thus preventing derailments and other accidents in time. Regular inspections using NDT techniques are crucial to the overall safety and reliability of railway systems.

NDT is also vital to maintaining the safety and reliability of vehicles. For instance, the technique is often used to inspect welds, castings, and other components to identify defects, address them early, and ensure the safe operation of vehicles.

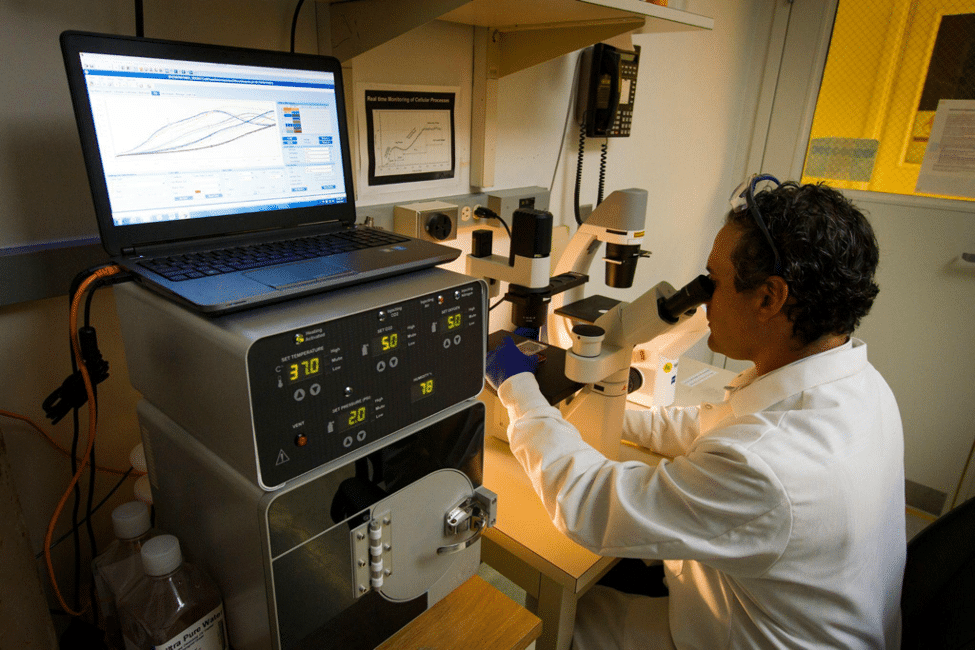

NDT in Advanced Healthcare and Biotechnology

The healthcare sector is another emerging application area for NDT. Non-destructive testing has become indispensable for medical imaging and diagnosis these days. X-rays, CT scans, and MRI are all NDT techniques that help visualize internal structures and detect abnormalities. Thus, NDT is crucial to diagnosing diseases, guiding surgical procedures, and monitoring patient progress.

NDT has many applications beyond medical imaging alone. It is being increasingly used to analyze biological materials and tissues through advanced methods like ultrasound and infrared spectroscopy. Healthcare professionals can study the properties of cells, tissues, and biomolecules using NDT for medical research, drug development, and disease diagnosis.

The technology is significant to improving healthcare outcomes and medical research today. NDT is shaping more effective treatments and better patient outcomes by enabling early detection and diagnosis of diseases. NDT techniques are also used in medical research to study the underlying causes of diseases and develop new therapeutic approaches.

Conclusion

Non-destructive testing has emerged as crucial to the safety, reliability, and sustainability of several advanced applications. From advanced manufacturing to energy infrastructure and healthcare, NDT provides the right tools to assess the integrity of components, prevent failures, and advance useful research.

As emerging technologies evolve, the demand for NDT and its applications will only increase. The need of the hour is more investment in NDT research, development, and innovation to meet the challenges of the future. What can become an even more vital tool for safeguarding our society and economy needs new approaches to address its current limitations.